# Lean Methodology

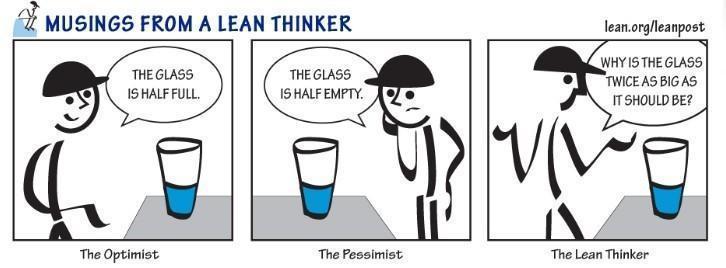

- Originally used as **Lean Manufacturing** used by Toyota. Remove waste in each

phase, so that only value is added.

- Implement Lean project management when you want to use ==limited resources,

reduce waste, and streamline processes== to gain maximum benefits.

> [!summary] 5 Principles of Lean

>

> 1. Define value

> 2. Map value stream

> 3. Create flow

> 4. Establish pull

> 5. Pursue perfection

## Fundamentals

- Eliminate Waste

- Look early and often for waste

- Anything that does not add value to the product/service

- Focus on business processes

- Mistake Proof your Processes ([[poka-yoke|Poka-Yoke]])

- Create ways to eliminate any chance for error

- Physical restrictions, visual cues, templates, workflow order

- Processes should be "Pull", not "Push"

- Pull: determined by customer demand -- only provide what is required

- Push: determined by process -- produce what we "guess" will be needed (or our forecast!)

- Defects are not made and/or passed along

- Defects are prevented whenever possible, but never moved to the next step in the process

- Level & Balanced

- Workload design based on demand (tact time)

- Minimize non-value-added steps

- Multi-skilled employees perform more than one task

## Wastes

- **Intellect:** Failure to fully utilize the time and talents of people; lack of training

- **Motion:** Any motion that does not; add value; chasing parts, signatures, tools, etc

- **Defects:** Any rework; errors

- **Overproduction:** Producing too much; producing too soon; batch processing

- **Extra Processing:** Adding inspections; approvals; reviews

- **Transportation:** Any nonessential transport or handling

- **Inventory:** High supply stores; finished product stores; in-work materials

- **Waiting:** Waiting on parts or documents, waiting for other workers or a machine

## Lean Tools

- [[5s|5S]]

- [[value-stream|Value-Stream Mapping]]

- [[kaizen|Kaizen]] -- Kaizen Blitz/Event

- Simplification

- Pull/[[kanban|Kanban]]/2-Bin System

- Visual Controls

- Error-Proofing ([[poka-yoke|Poka-Yoke]])

- Set-up Reduction

- Total Productive Maintenance

- Standard Workd

- Gemba Walks

- Leader Standard Work

## Challenges

- Buy-in from entire team

- Current attitudes

- Trust as a core building block

- Future commitments

- Sustaining gains

- Continuing to improve

- Cultural change